Absorption system for greenhouse

From the lab test to real application

ZHAW is testing at the facility lab of the Institute of Energy Systems and Fluid Engineering (IEFE) the configuration of the absorber with packing materials inside.

The absorber has been tested under different air inlet conditions and for different set points for the required air temperature and humidity at outlet. This absorber can operate in both direction of absorption process, that means for the it has been used also as desorber.

The particular configuration has been designed for the operation in the greenhouse of Swissorchid in Wangen bei Dübendorf (CH) (Fig. 1). The orchid greenhouse company strives to produce as ecologically and environmentally friendly as possible and implemented already in the last years some energy-saving measures.

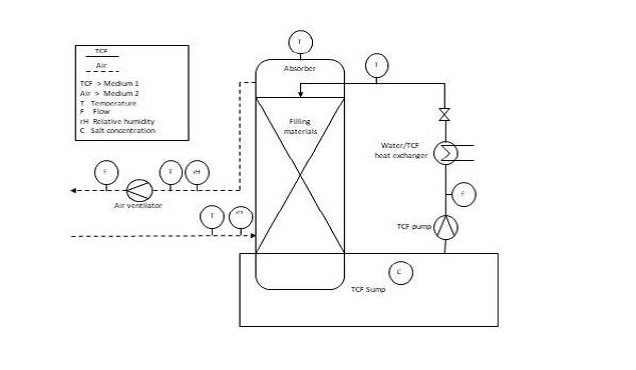

The inlet air temperate (T2.1) is set up in the water/air heat exchanger (Fig. 2) while humidity (rh2.1) is set by the humidifier (boiling water pots). The air temperature (T2.3) at the outlet (demand side) is controlled by changing the TCF temperature at inlet (T1.1) through the water/TCF heat exchanger while the air humidity (rh2.2) is as result of the TCF concentration (C1.1). There is no automation in the test bench; the flowrate of media are controlled by manual valves/flaps. The concentration is not continuously monitored, TCF samples are taken from the sump and measured. The air temperature is measured at the absorber top as well as before the ventilator.

The measurement points of this first prototype allow an energy and mass balance around the absorber and serves as validation for simulation of the equilibrium at the outlet of the absorber.

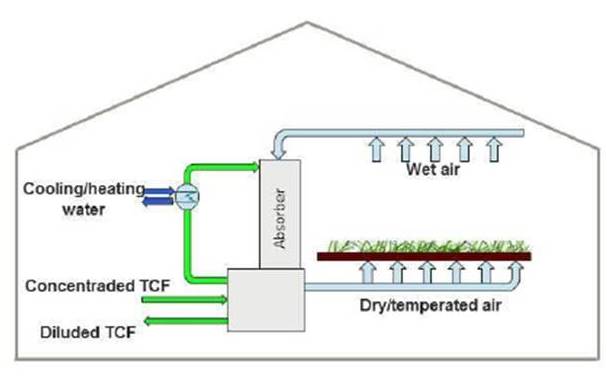

The greenhouse selected for the demonstrator has a surface of 600m2. Here are installed 9 absorbers. In order to minimise the energy requested (i.e. the thermo-chemical potential) to provide the right air conditions for the orchids, an innovative air distribution system (Fig. 3) is tested inside the demonstrator. Through this new air system the air temperature and humidity is controlled directly closed to the crops and the conditioned air is blown directly below the crop tables. The main advantage is that is not anymore necessary to treat the air of the entire room, but only the air in contact with the crops with a significant energy saving. Furthermore, it is possible to create micro-climate inside the same room in case there are different types of plants or plants in different growing phases.

Each absorber has a separated TCF recirculation circuit that allows testing contemporaneously different TCF in different absorber that means it will be possible to compare different TCF working under identical and real conditions.

For the theoretical equilibrium at the absorber outlet, the air temperature should be the same to the TCF inlet temperature, that means setting the inlet TCF temperature is possible to control the air outlet temperature. The discrepancy between theoretical and real temperatures is analysed in lab tests in order then to be able to control the air temperature controlling the TCF temperature through a motorized valve.

The first demonstration period is planned to start in the next weeks.